First chopper attempt

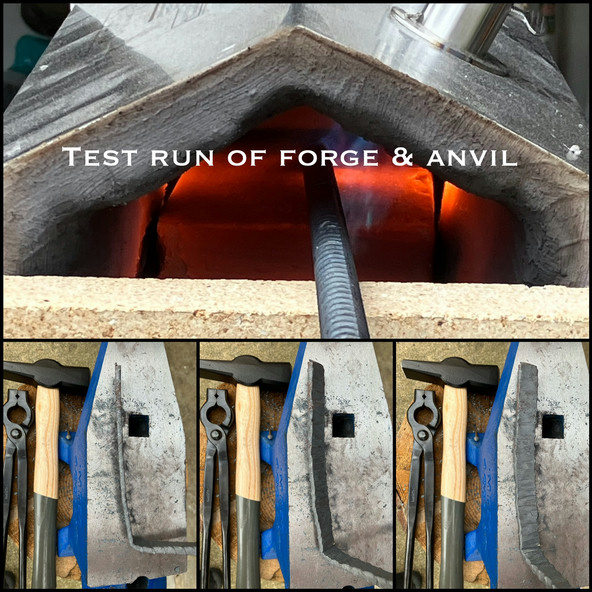

First run of the home forge

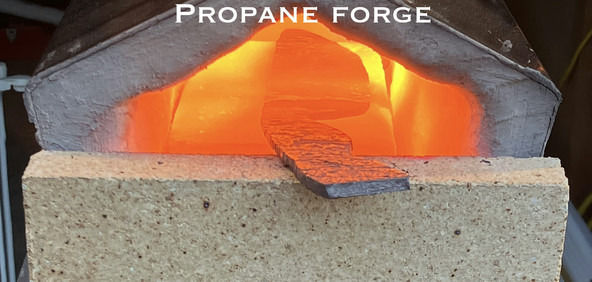

Before starting work on my nice piece of knife steel, I wanted to test the end-to-end operation of my propane forge and other recently acquired blacksmithing tools. This was mainly dialing in the propane regulator/valve settings, but I also wanted to get a feel for the hammer, tongs, and anvil. I used a piece of rebar for this, and everything went smoothly.

First attempt at forging a blade at home

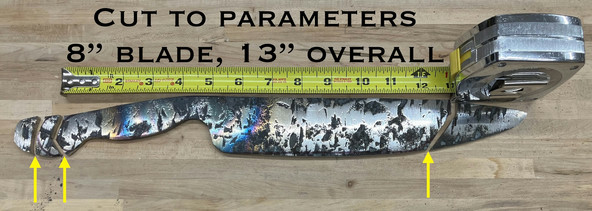

Next I was ready to start my real project: making a (smallish) chopper...

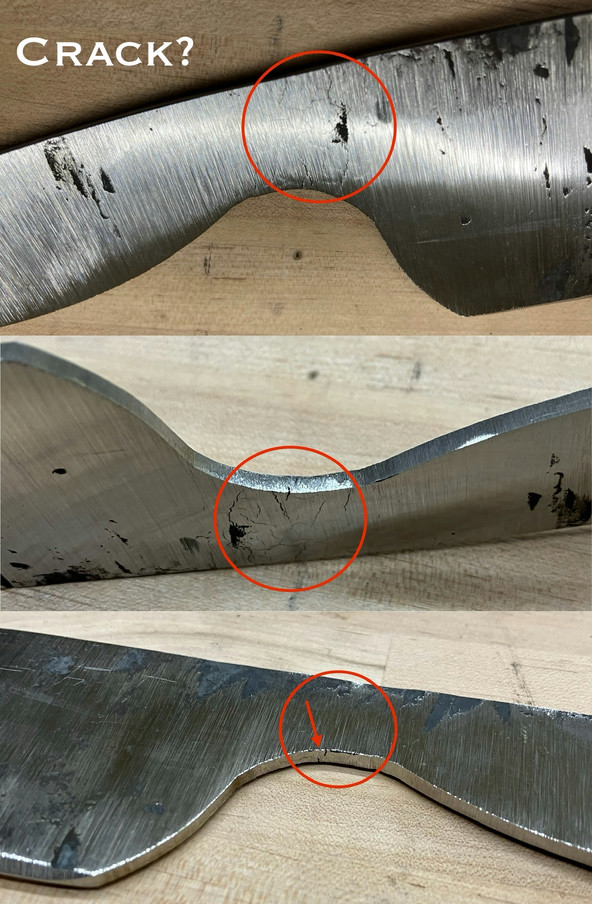

Results

Unfortunately I was not able to grind the cracks away, and some of them appear to go almost halfway through the thickness of the steel. This area of the knife, where the handle meets the blade, will be subject to the highest levels of stress, so these cracks seem likely to result in a critical failure.

I'm unsure whether it's possible to fix these cracks without welding, so I'm seeking input from experienced bladesmiths to determine if this is salvagable as a chopper. Worst case, I'll cut off the handle and then repurpose the blade section into a smaller complete knife.